A Deep Tour on LED Phosphor Part I: What is LED Phosphor?

What is LED phosphor?

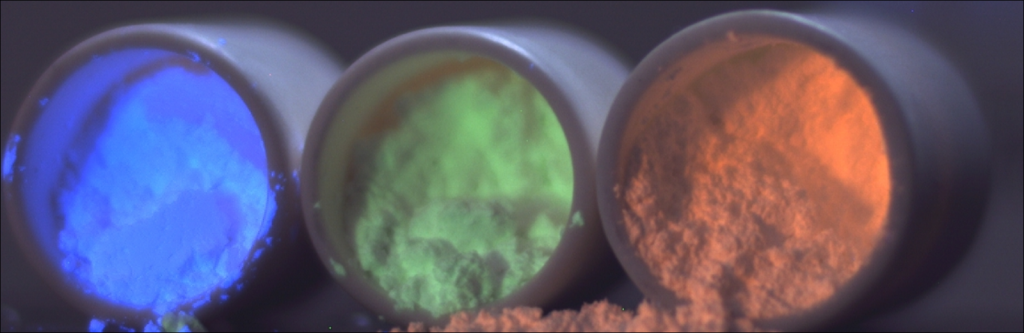

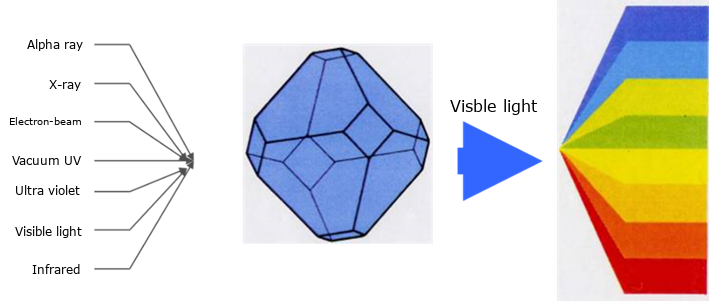

LED phosphor, in a narrow sense, is a kind of Photoluminescent materials can absorb the energy of violet and blue light from gallium nitride or other LED chip, and transform it into visible light. Phosphors are made of solid luminescent materials, which can absorb blue light (450-460 nm) and release green, yellow, orange or red light, on the present mainstream LED market. These kinds of emission can mix the blue light from LED chip at a certain proportion for application in lighting, backlit display or other fields. For example, Ra > 80 white light illumination is realized by 450-460 nm blue chip + 530 nm Ga – YAG green phosphor + 630 nm nitride (1113 system) red phosphors; and NTSC > 100 high color gamut LED backlit displays are obtained by 450-460 nm blue chip + 530 nm nitrogen oxides (β-Sialon) + 630 nm fluoride (KSF) red phosphors. With the growing demand of society, the concept of LED phosphors is expanding. Since 2018, the demand and research has been extending continuously in the field of solar spectrum, infrared, ultraviolet and vacuum ultraviolet, MINI LED and so on. Based on this, the generalized LED phosphors can be defined as the inorganic luminescent materials to absorb electromagnetic radiations at a certain wavelength, such as ultraviolet, visible and infrared light, and convert energy into radiations at required wavelengths. The phosphor luminescence process is shown in the Figure 1.

LED phosphors have several classified methods under different circumstances. According to applications, phosphors can be divided into phosphors for backlit display, white light lighting, medicine, security, agriculture and agricultural and sideline products, etc. On the basis of energy sources, phosphors can be divided into vacuum ultraviolet phosphors, near ultraviolet phosphors, violet light LED phosphors, blue LED phosphors, etc. In terms of luminescence wavelengths, phosphors can be divided into ultraviolet, blue, green, yellow, red and infrared phosphors, etc. According to raw materials, phosphors can be divided into silicates, phosphate, aluminate, oxide, nitride, fluoride, and sulfide phosphors, etc. Basically, phosphors are involved in every aspect of industry and our life, with differences in performance requirements under various circumstances. Overall, manufacturers and customers of LED phosphors commonly use optical properties (emission light colors, CIE coordinates, light wavelengths), granularity characteristics, and stability (aging performance) to distinguish the merits of the phosphor performance.

As the main source of LED phosphors excitation energy, electromagnetic radiations can be obtained by inert gas discharging, violet light semiconductor chips, blue light semiconductor chips, etc. Excitation energy can be made into light emitting device carrier by a specific process route. Thus, the LED phosphors can be applied on the device and the photoluminescence process can be realized. Take white LED lighting as an instance, LED lamp can be encapsulated by mixing up the red and green phosphors with silica-gel-based materials at a certain proportion and then coating them on gallium nitride LED blue chip. The blue chip emits 450-460 nm blue light when powering up. A part of blue light is absorbed by YAG powder (yellow), Ga – YAG powder (green), SCASN phosphors (such as nitrides 1113) and then the powders emit the corresponding color. Different CCTs (correlated color temperature) and CRIs (color rendering index) of white light illumination can be adjusted by mixing the color of light emitted by phosphors and the transmissive blue light at a certain proportion. Compared with the white LED devices, the processes of the LED phosphors are different for LED backlit display, UV, infrared and other applications. But the luminescent mechanism of these applications is basically the same, which is the excitation energy from a specific light-emitting device being absorbed by the LED phosphors and then being converted to the corresponding wavelengths of light (electromagnetic waves) to meet the lighting requirements. While the above luminous requirements depend on the part of the LED chips, LED powders, LED device packaging technologies and other LED related parts. Among them, the core of luminous performance depends on phosphors, chips and LED packaging technology. So far, the core technique and technology of the chips is still under the control of a few foreign companies. Compared with other factors, the differences of LED chip performance is negligible because of the monopoly of LED chip technology. In practical applications, encapsulation technology and LED phosphors become the determinants of LED device performance. Beijing Nakamura Yuji Technology Co., Ltd and Beijing Yuji Xinguang Photonics Technology Co., Ltd,affiliated with Yuji Group, possess the state-of-the-art technology of LED phosphors and LED packaging respectively, and occupy the leading status of market in their respective fields.