Why High Price For High-quality LED Products? Part – 1

#1-LED LEAD FRAME

Part – 1

As a consequence of LED technology development and its widespread adoption, prices are falling substantially and continuously in the LED lighting market. While price wars are everywhere among manufacturers, suppliers, and sellers, products of similar types still vary largely in price. As a consumer (or at least a potential one), are you just getting high with the lowering price? Have you ever thought about the stories lying in the price difference? Do you know how that would affect the products’ quality and user experience? Most importantly, what should you keep in mind before and during purchasing?

Though the price might be the first consideration for a large portion of consumers, it should never be the only one. A small step further will greatly benefit you: a better knowledge about the components and their qualities will help find the most cost-effective product for your needs, for they are the dominant factors of the price and quality of the eventual product.

From this post on, we will discuss the key components of LED products one by one and analyze the raw materials from the perspectives of their qualities and costs. We hope this series can help you grab a general idea of the LED producing process and figure out where every penny you pay goes. Now, let’s begin with our first component–LED LEAD FRAME.

A Brief Introduction

A lead frame is a metal structure encased in a transparent plastic cap. It protects the crystalline wafer and the wires, helps silicone molding, provides electrical connection, and influences the optical and electrical properties. The performance of an LED light depends directly on the lead frame’s structure.

Metal substrates and resins are the main components of an LED lead frame. Due to the demand for both electrical and thermal conductivity, the substrate is usually made from iron or copper, such as red copper when applied to high-end products and brass or iron to low-end products. Also, the surface of the metal needs to be electroplated to improve electrical conductivity and corrosion resistance. Meanwhile, part of the frame is made from engineering plastics (organic polymers) to be insulated, where materials such as EMC, PCT, or PPA are commonly used.

Material Selection 1: Metals

Copper (chemical symbol Cu) has a history of use of at least 10,000 years and is one of the earliest metals humans has discovered. A freshly exposed surface of pure copper has a reddish-orange color, usually called red copper. It is also one of the most favorable pure metals, for it is a malleable and ductile metal with very high thermal and electrical conductivity. Different additions to copper make different alloys. Several best-known types are brass, where zinc is a significant addition, and cupronickel, where nickel is used. As for bronze, any addition other than zinc and nickel is added. Copper and most of its alloys have high resistance against corrosion and static stability in a dry atmosphere.

C19400 (also known as C194), developed by Olin Brass (a leading manufacturer of copper alloys in North America), is an alloy used worldwide for a variety of applications including electrical lead frames. It is highly thermally conductive and has a similar electrical conductivity of over 90% as much as pure copper.

C192 (known as KFC) costs more or less the same as C194, with an electrical conductivity of 60% that of pure copper.

C2680, a kind of yellow brass, is among the highest zinc-containing brasses. Though it’s mainly used in jewelry and metal wares, it has been found on low–the end LED markets. It is inferior to C194 and C192 in ductility, malleability, heat dissipation, and of course, electrical conductivity (less than 30% compared to pure copper). Since lower thermal conductivity usually comes with lower electrical conductivity, C2680 only shows one-third of pure copper’s thermal conduction coefficient, which means that products using it have larger thermal resistance and lower light output. But since zinc costs two to three times less than copper, C2680 is much cheaper than the other two, making it popular among manufacturers.

Different manufacturers have different positioning strategies and preferences for materials. High-end products always adopt C194, C192, or red copper. These alternatives excel in electrical and thermal conductivity and malleability as well, enabling themselves to be hot and cold-forged. In low-end markets, C2680 has been increasingly used recently.

Although most lead frame manufacturers from China claim that they use C192 or C194 for lead frames, it is not always the case. Driven by industry trends, many manufacturers resort to cheaper materials and simpler techniques. Most of them are using indigenous Chinese red copper.

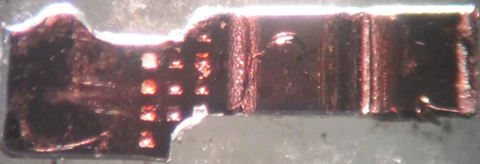

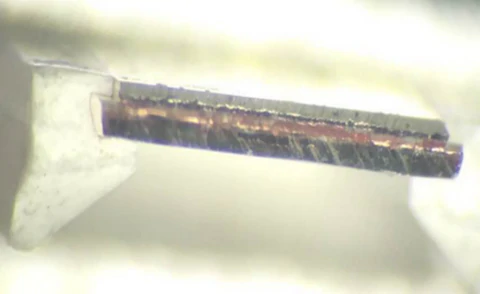

Here is a tip for distinguishing the alloy’s type: cut the heat sink of a frame so that it shows a cross-section, then you can tell from the color what type of alloy it is. The figure above shows a reddish new surface, suggesting the material being used is red copper.

Another key point concerning metal is electroplated coating. Coated copper substrate and lead frame provide the electrical connection from the gold wires to the printed circuit board and the thermal path from the LED die. The thickness and quality of the coating greatly affect the luminous flux and welding performance afterward. Normally silver is used for coating, yet quite several manufacturers replace it with nickel. They coat silver only above the functional area (some even shrink to the die bond) and use nickel for all other parts.